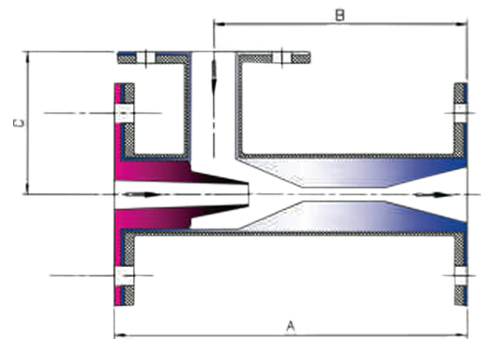

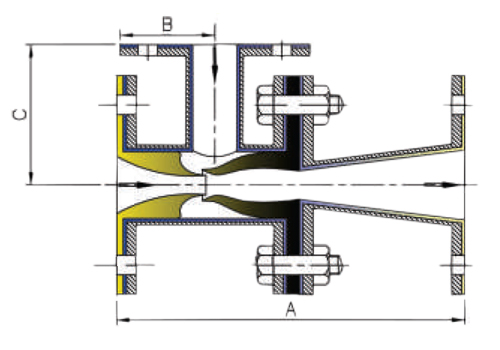

Our Ejectors deliver chemicals more safely and with greater precision and reliability than traditional delivery methods. There is no moving parts, ejector system is also a safe system because the injected material is not under pressure. If the water flow stops, injection stops instantly. Simple to use and self-priming, Our ejectors are able to run dry with no problems and because they are made with special lined material & they last longer.

The system uses differential pressure between inlet and outlet ports to create a vacuum, which draws chemicals through the suction port. Internal mixing vanes help ensure even distribution and installations do not require a pump or motor.

- Excellent safety because injected material is not under pressure; if water flow stops, injection also stops instantly

- No moving parts means excellent reliability, ZERO maintenance

- Uniform distribution of material means accurate delivery

- Simple to use and self-priming

- Able to run dry with no problems

- Ebonite lined / PP Lined corrosive resistance material means long wear life

Sr.No. |

Ejector Model No. |

Nozzle Bore IN MM |

Throat bore in MM |

Connection in NB |

A |

B |

C |

|||

|---|---|---|---|---|---|---|---|---|---|---|

Power Water |

Suction |

Delivery |

M³/Hr |

|||||||

1 |

Aditya 62 |

4 |

10 |

20 |

20 |

20 |

1.7 |

103 |

61 |

63 |

2 |

Aditya 63 |

5 |

12 |

20 |

25 |

25 |

2.45 |

163 |

94 |

87 |

3 |

Aditya 64 |

6 |

16 |

20 |

33 |

33 |

4.36 |

208 |

118 |

89 |

4 |

Aditya 65 |

16 |

20 |

65 |

32 |

65 |

16.36 |

347 |

56 |

102 |

5 |

Aditya 66 |

10 |

23 |

33 |

40 |

50 |

9.81 |

293 |

190 |

102 |

6 |

Aditya 67 |

12 |

33 |

40 |

50 |

50 |

17.45 |

319 |

208 |

111 |

7 |

Aditya 68 |

16 |

40 |

50 |

80 |

80 |

27.27 |

366 |

244 |

127 |

8 |

Aditya 69 |

20 |

48 |

65 |

80 |

100 |

39.27 |

394 |

266 |

127 |

9 |

Aditya 70 |

25 |

64 |

80 |

100 |

100 |

69.82 |

450 |

303 |

127 |

10 |

Aditya 72 |

40 |

95 |

125 |

150 |

200 |

157.1 |

773 |

559 |

152 |

Sr.No. |

Ejector Model No. |

Nozzle Bore IN MM |

Throat bore in MM |

Connection in NB |

A |

B |

C |

|||

|---|---|---|---|---|---|---|---|---|---|---|

Power Water |

Suction |

Delivery |

M³/Hr |

|||||||

1 |

Aditya 40 |

6 |

9.52 |

40 |

25 |

40 |

2.18 |

21 3 |

60 |

86 |

2 |

Aditya 40 |

10 |

11.43 |

40 |

25 |

40 |

5.72 |

213 |

60 |

86 |

3 |

Aditya 50 |

12 |

17.46 |

50 |

25 |

50 |

9.54 |

279 |

54 |

95 |

4 |

Aditya 65 |

16 |

20 |

65 |

32 |

65 |

16.36 |

347 |

56 |

102 |

5 |

Aditya 80 |

19 |

25.4 |

80 |

40 |

80 |

24.54 |

411 |

68 |

111 |

6 |

Aditya 100 |

25 |

30.16 |

100 |

50 |

100 |

43.63 |

500 |

78 |

133 |

7 |

Aditya 125 |

32 |

39.11 |

125 |

65 |

125 |

60 |

612 |

83 |

146 |

8 |

Aditya 150 |

40 |

44.45 |

150 |

80 |

150 |

90 |

760 |

94 |

159 |

Body Material Mild steel with Ebonite Rubber Lined, Nozzle & Throat PP, (Optional HDPE, PP/FRP Lined, Stainless Steel also available)

We are doing Design, Engineering, Manufacture , Supply , erection and commissioning of Following

plants. We are using advance design software like Auto cad Plant 3D,Solidworks Premium, Procad for

3D modeling of Water treatment plants.