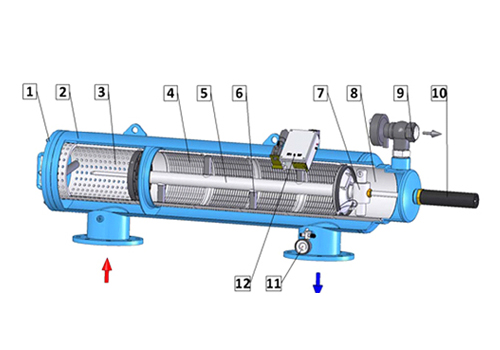

Self cleaning (auto backwash) filters combine the advantages of high quality filtration from different water Sources (Sewage, Reservoirs, River, etc.) with self cleaning features, where the flow is uninterrupted during the filtration process. The filters are designed for use in a wide range of industrial, municipal and irrigation applications.

The main element is made of stainless steel with a large filtration open area for water flow in order to Withstand high dirt load and pressure. Cleaning of the screen is performed once the pressure loss across the filter has reached the present value (up to 0.5 kg/cm2) The filter is equipped with a coarse screen that protects the finer screen from stones and larger particles. The flushing valve opens and pressure is released from the hydraulic piston, then water flows outside through the flushing valve. Pressure in the hydraulic motor chamber and the dirt collector is significantly lowered. The dirt collector nozzles movement and rotation cleans the screen's entire internal surface. The flushing cycle takes 10 seconds. The flushing valve closes at the end of the cycle and the filter is clean. During the cleaning cycle, the filtration process Remains uninterrupted. Hence you will get filtered water continuously.

| TECHNICAL SPECIFICATIONS | |

| Materials | |

| Filter body | Mild steel with rubber lining / Mild steel with power coating / mild steel with epoxy coating / stainless steel |

| Flow Rates | up to 1500 m3/hr |

| Filtration Range | 80 to 500 micron |

| Max Working | up to10 kg/cm2 (150 psi) |

| Pressure | |

| Min Pressure | 2 Kg/cm2 (30 psi) |

| During Flushing | |

| Max Temp | 65° C (150° F) |

| Clean Screen | up to 0.1 Kg/cm2 (1.5 psi) |

| Pressure Loss | |

| Inlet / Outlet | Flanged 4”-16” |

| Inlet/outlet parallel. | |

| Standard | Hydraulic Controller or Control panel |